The Bronco Restoration Project

Table of Contents

The Wing

A large part of the Bronco Restoration Project has been the decision-making around the treatment of the wing. Unfortunately, what is believed to be the original wing of the 639 is in very poor condition- all the fittings and control surface attachment points are very badly damaged or corroded, as you can see from the images below. A rough estimate of the time to repair the original wing would be in the vicinity of 3800 sheet metal man-hours (1,143 days!!) so the decision was made to source a replacement wing.

The Bronco team looked around for different options and found an appropriate wing assembly, which we later found out as an added bonus, has Australian provenance!

Earlier this year, Kim ‘Woody’ Wood flew to the US to visit Marsh Aviation- a workshop in Mesa Arizona where they re-configure aircraft for fire-fighting purposes. Woody spent four days here, picking up our new wing and some other components that we were interested in- horizontal stabilisers, elevator assembly and various other small parts, and squeezing it all into a shipping container.

Packing the container

When the container arrived, the team set about building up the freshly acquired wing to make it fit our aircraft. The tailing edge flap, wing tips and spoilers were the only parts of the original wing that we could recover, and these will be used on our new wing.

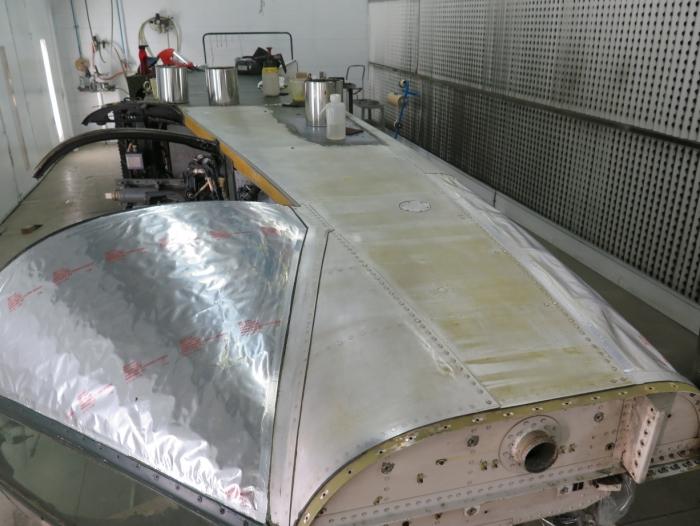

Our new wing was not in perfect condition so some conservation work has been required to get it back into shape. The new wing had some minor corrosion and a small amount of hangar rash that needed attending to, and the wing tips on the new wing were badly damaged, so they have been replaced with the original wing tips.

Finally, the wing will be painted to resemble our colour scheme, and then put in place on the fuselage.

Preliminary planning

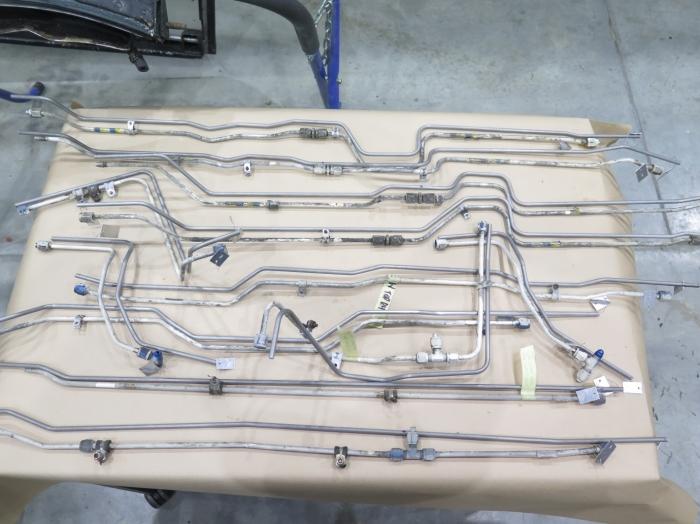

A considerable amount of work is necessary to make aircraft available for display and interpretation. When Bronco 67-14639 was received by the Memorial it was basically intact, but had suffered from long exposure to tropical weather and reclamation of parts for use on other aircraft. Minor electrical fittings, connectors and clamps, and most of the fuel and hydraulic plumbing had suffered corrosion, and almost all of the ferrous fastenings were badly corroded.

Many parts have been removed and must be replaced. Salt-laden air has corroded metal fastenings into unrecognisable lumps that must be cut or drilled out to gain access to panels.

Corrosion is a significant issue with the Bronco structure

The cockpit floor armour was also corroded. The canopy Perspex had become quite crazed and was largely opaque, while the trimming strips around the canopy had delaminated. Most fabric and rubber components have become brittle or damaged. The wing structure had suffered particularly badly, and was not thought capable of bearing its own weight.

The aircraft required significant intervention effort to stabilise corrosion, and to ensure the long term stability and safety of the airframe. This work must be done, however, with minimal intervention, and in such a way that it maximises the survival of parts of the aircraft which have been identified as significant. Detailed examination of the aircraft’s structure, identifying and dating elements, understanding when various components were added or removed, and making assessments of the significance of each element was a key part of the preliminary work.

Work on the aircraft commenced in 2016, with the formulation of a comprehensive project management plan giving details on necessary resources, delivery timelines, milestones, risks, and the aim of the project.

The project has identified that the aircraft’s significance to the National Collection flows largely from its association with key periods and individuals in the Vietnam War. The project will therefore involve the removal of post-Vietnam era modifications and paint, and see the airframe presented as it was on 13 July 1970, a day in which it flew on two separate missions with Australian crews. The livery and armament will be based on images of the Memorial’s airframe on the tarmac of an Australian detachment in Vietnam. The scope of work includes mitigating active corrosion throughout the airframe, acquisition and fitting of missing aircraft components, repairing and replacing components to Vietnam era configuration and ensuring an accurate paint scheme and markings. According to current estimates of the work required and other foreseeable commitments for the Large Technology Object and Aircraft Conservation Teams, the project can be completed in mid-2019.

Hands-on work commenced in 2017. Some of the initial steps undertaken to December 2017 are shown in the photos and video below. Watch one of our conservators, Woody, describing composite repairs.

Identifying and treating corrosion

Removing the canopy

Stripping the fuselage

Repairing mechanical damage

Removing and cleaning fittings

Removing rubbish and rats nests

The Repair of the Inboard Horizontal Fin Centre Fairings

These images specifically show the repairs to a torn splice doubler and large crack in the fairing, located on the tailplane. The images show just how much clamping and attention to detail is required- there are many steps! All this repair work was achieved with the use of the same materials originally used to manufacture the item.